You’ve got a brilliant idea – you’re sure your product could be a huge success in the market. But what happens next? Depending on the type of product, the size of the project and other factors, the product development process can be quite complex.

Indice dei contenuti

What are the key questions to ask yourself at the very beginning?

Before you start the development process, it is crucial to have a clear idea of the product, the market and the potential customers. It is a good idea to have a list of questions and answers at the start of the process:

- What problem or need does my product resolve?

- Who are my target customers?

- Who are my competitors and what do they offer?

- What is the market demand for the solution I am offering?

- What are the production and development costs?

- What are the potential threats and risks in developing and launching the product?

- What budget and timeframe do I have for the whole process?

It could be argued that this is fundamental for the development and launch of a successful and profitable product. It is also necessary to be aware of the challenges that most often arise in the process itself.

The most common challenges in the development process

– The need to coordinate different products and experts: the more complex the product, the more difficult it will be for one person to do all the work. The development process needs to involve different experts and departments within the company. R&D, design, production, marketing and sales are all involved in the process and there is a challenge of coordination as these groups may have different interests and objectives.

– Time and budget constraints: Complex products require much more time and money, which can quickly become a challenge in achieving product development goals. If we waste too much time on the whole process, competitors can quickly overtake us and the work we have done. We need to keep a close eye on the competition and how the market develops and changes.

– Technical demands and product complexity: Some products require a high level of technical knowledge to develop. Specialised tools and technologies need to be used, which can significantly increase the cost price of the product and therefore its future selling price.

– Compliance with regulations and standards: There are certain laws, regulations and standards that must be met and enforced by the country or the European Union. The complexity of the process is increased by ensuring compliance with different safety, environmental and quality standards.

– The need to adapt to changes: As the time from conceiving an idea to launching a product can be longer than expected, it is essential to adapt and evolve our solution according to changes in the market, internal development goals or customer feedback.

These challenges contribute to the complexity of the product development process, along with other factors. However, with the right project management, methodologies and collaboration between departments and experts, potential pitfalls and risks can be avoided.

What does our own engineer have to say about the development of fitness equipment?

When we asked our mechanical engineer how he would describe the process of developing a new piece of fitness equipment, he simplified it all: “We decide what the next piece of equipment we are going to develop is going to be, then we do all the necessary research, measurements, calculate all the forces and angles, think about the biomechanics and finally, we start designing”. Well, let’s keep in mind that Denis has already developed a whole range of products and we could say that he is an expert. But it’s not all as smooth and easy as that. So let’s take a closer look at how the processes work in practice.

How do we come up with ideas at KingsBox?

“They always let me make whatever I want, so when I watched the transformer’s movies, it seemed like a logical idea to use inspiration from there on our machines” Denis joked.

No, actually it’s like this: A good track record is key for us because ideas come from many different channels. The company collects and records all the ideas that are ever generated. Some are the result of our own experience, some are suggested by users, and some are the result of constant market research and the desire to innovate and improve existing products on the market.

Setting objectives is the basis for further development

At the beginning of each quarter, each department sets objectives for what it wants to achieve. For example, the development department draws up a list of products to be developed in the current quarter, based on the market situation, demand and expansion of the existing range. Projects are assigned to members of the development team, who are then responsible for the entire product development process – taking an idea from paper to product launch and sales.

Before we get started, we carry out a so-called “design brief”.

Before the development of a product begins, a meeting is held which results in what is known as a design brief. This is a set of criteria, ideas, requests, requirements and examples of good practice. They are used as a guide for the design or the development of a new product.

Design Thinking; the five-phase development process

Now we are ready to start developing a product. We use the ‘Stanford Method’ for the development process, better known as ‘Design Thinking’. This method uses a creative problem-solving approach and puts the user and their needs at the centre of the process. This method has five phases:

- Empathy: Building empathy requires observing users in the environment in which the product will be used, asking users about their experiences of using similar products and their own experiences based on their own engagement with the products.

- Defining the problem: This process is based on synthesising or combining the information gained from empathy.

- Ideation: The aim is to generate as many possible solutions to the problem as possible. It’s important to think broadly and outside the box. We use a variety of tools in the ideation process. It starts simply with a pencil and a sketchbook, where the product is sketched by hand to generate as many concepts as possible. The next step is refining the most promising concept and creating a 3D model in SolidWorks.

- Prototype: Testing is the most effective way to validate solutions. Building a prototype, whether fully functional or very simple, provides insight into the whole design process. It puts ideas to the test. The results of testing provide excellent feedback that can be used for modification. Most of the products developed by KingsBox are made from steel, either sheet metal or various tubes and profiles. The predominant machining processes are laser cutting on a surface or tube laser, sheet metal bending, welding (MIG, MAG; TIG), turning, drilling, threading, chrome plating, zinc plating, powder coating, etc.

- The testing of ideas can take place at any stage in the design process, but it is most often carried out after the prototype has been built. It tests the performance and functionality of the product, its durability, stability and ergonomic suitability.

When all the components needed to build a prototype arrive at the company, they are inspected by a competent engineer and checked for build suitability. The prototype is then assembled and tested in 3 stages:

- Assembly and accuracy of fit

- Load capacity, stability and safety

- Functionality and usability

Sales staff and other employees need to know the functionalities of the products

The developed product is presented internally to employees to keep everyone up to date with the existing product range and its intended use. The main focus is on the sales department, as it is the salespeople who are in charge of the product’s presentation to potential customers. This also completes the development team’s main work on the product in question. In the future, the development team will remain available to solve any problems, answer questions and support the sales team or any other department in the company.

From here, marketing takes over, with product photography, video creation, product presentations to end customers, advertising and campaigns.

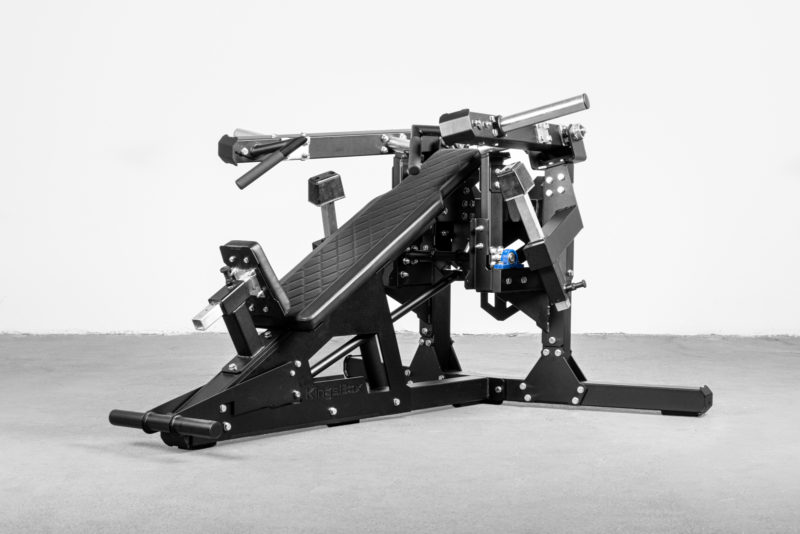

Finally, we would like to highlight a nice thought from Denis, who has left his mark on Mad Series fitness machines: “I want to change the fitness industry and with the Mad series, I am making a big statement.”

We invite you to take a look at the Mad Series on our website – we have recently launched the outstanding Savage Prince chest press which is getting a lot of excitement. If you want to find out more about the development of this one, check out the youtube video.